When buying a mass flow controller, the accuracy specification that is published on the data sheet is important criteria to evaluate. In fact, accuracy is so important that you need to look beyond the published accuracy statement because the published accuracy does not necessarily represent the actual process gas accuracy that will be achieved.

Nothing Like the Real Thing

Calibrations are typically done against a reference device or calibration standard using a surrogate calibration gas such as nitrogen or air. Surrogate gasses are used because it can be difficult and expensive to test and calibrate a device on the actual process gas. When a surrogate gas is used, a conversion factor or conversion function is applied to that surrogate gas calibration to set up the device for the specified process gas. This conversion factor is based on the specific heat of the process gas vs the specific heat of the calibration gas. This conversion factor approach may introduce some additional inaccuracy depending on the properties of the process gas. There’s nothing like the real thing… The best possible accuracy is delivered when the device is calibrated directly on the customer specified process gas and at the process conditions.

Characteristics of Carbon Dioxide

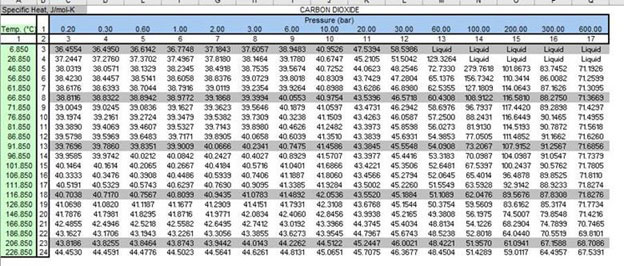

Carbon Dioxide is a refrigerant which makes its conversion factor (specific heat) highly pressure dependent. The specific heat of CO2 varies over temperature and pressure (see below), so the use of a single “calibration”, “sensor” or “correction” factor will result in additional inaccuracies at different temperatures and pressures. At higher temperatures and pressures the variation in the specific heat increases dramatically.

Figure 1: Specific heat of CO2 by temperature and pressure

How We Do It

At Brooks Instrument, we use traceable calibration standards for all our mass flow calibrations to ensure that we meet our published specification. And, to provide our customers with the most accurate mass flow controllers for carbon dioxide applications, we calibrate the 5800 Series, SLA5800 Series and SLAMf Series MFCs on carbon dioxide (i.e. calibrated on the real thing). This allows the user to control the exact desired amount of CO2 with no offsets or hassles. Brooks Instrument also uses actual gas calibrations for Argon, Helium, Hydrogen and Nitrogen.

For additional information on mass flow controller accuracy see our blog post, “Understanding Mass Flow Controller Accuracy.”

For assistance selecting the most accurate MFC for your application, please contact our Applications Engineering team or your local Brooks Instrument representative.

Component datasource missing. Select a datasource for this component.