What is the “usable” range of a mass flow controller? Is usable range the same as turndown ratio? Before we answer these questions, let's make sure we’re all grounded on the basics, like what is a mass flow controller (MFC) and where are they used.

Mass flow controllers combine a flow sensor, control valve and on board control electronics in a relatively small integrated package capable of automatically measuring and controlling the flow rate of a given fluid to the users specified flow rate (View Theory of Operation video.). Gas flow controllers are used in a variety of industries and applications, including semiconductor chip manufacturing, chemical process research, glass and metal coating, solar cell and fiber optic manufacturing, food processing and biotechnology processes.

What do we mean by usable range and who should care?

Let me start with an analogy. If you’re buying a car and the salesperson tells you that the car has a top speed of 250 miles/hr (402 kilometers/hr), what is the usable range of that capability? Well, it may depend if you’re driving on the autobahn in Germany or through Staten Island in New York City. But we can all agree that having the ability to go that fast - and actually being able to take advantage of it - are very different things. Drivers on Staten Island, New York might never get to drive above 50 miles/hr (80 km/hr) so the entire range from 50 to 250 mi/hr (80 to 402 km/hr) would not be usable, and having that ability provides no real benefit. In a similar way, having a mass flow controller with a wide turndown may sound great, but can you really take advantage of that capability? The answer is, it depends on the specific application. The needs in a chemical process research application are very different from a food & beverage application or a thin film deposition application.

So let's come back to gas flow controllers and the elements that impact the usable range. When we say usable range, we mean the range from the maximum measurable flow rate of the device, also known as the full scale range of the device, to the minimum that provides good meaningful results for the process. The minimum is often limited by the flow sensor’s ability to provide a clean stable accurate signal and or the control valve’s ability to maintain stable flow control at both high and low flows.

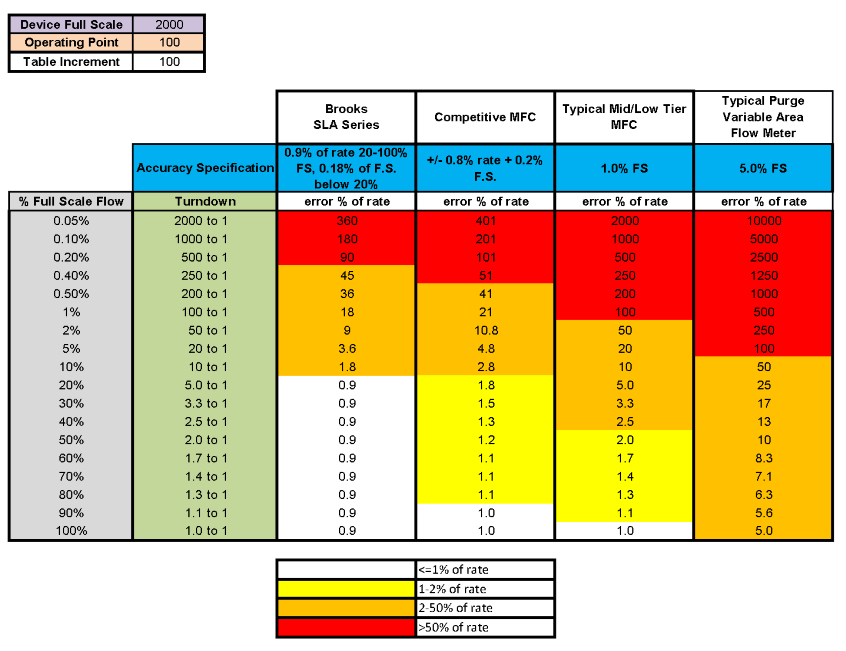

The table below shows some accuracy specifications of typical mass flow controllers as well as a variable area flow meter for comparison. The table shows several points across the available range of the device and highlights areas where the device may not be usable in some applications.

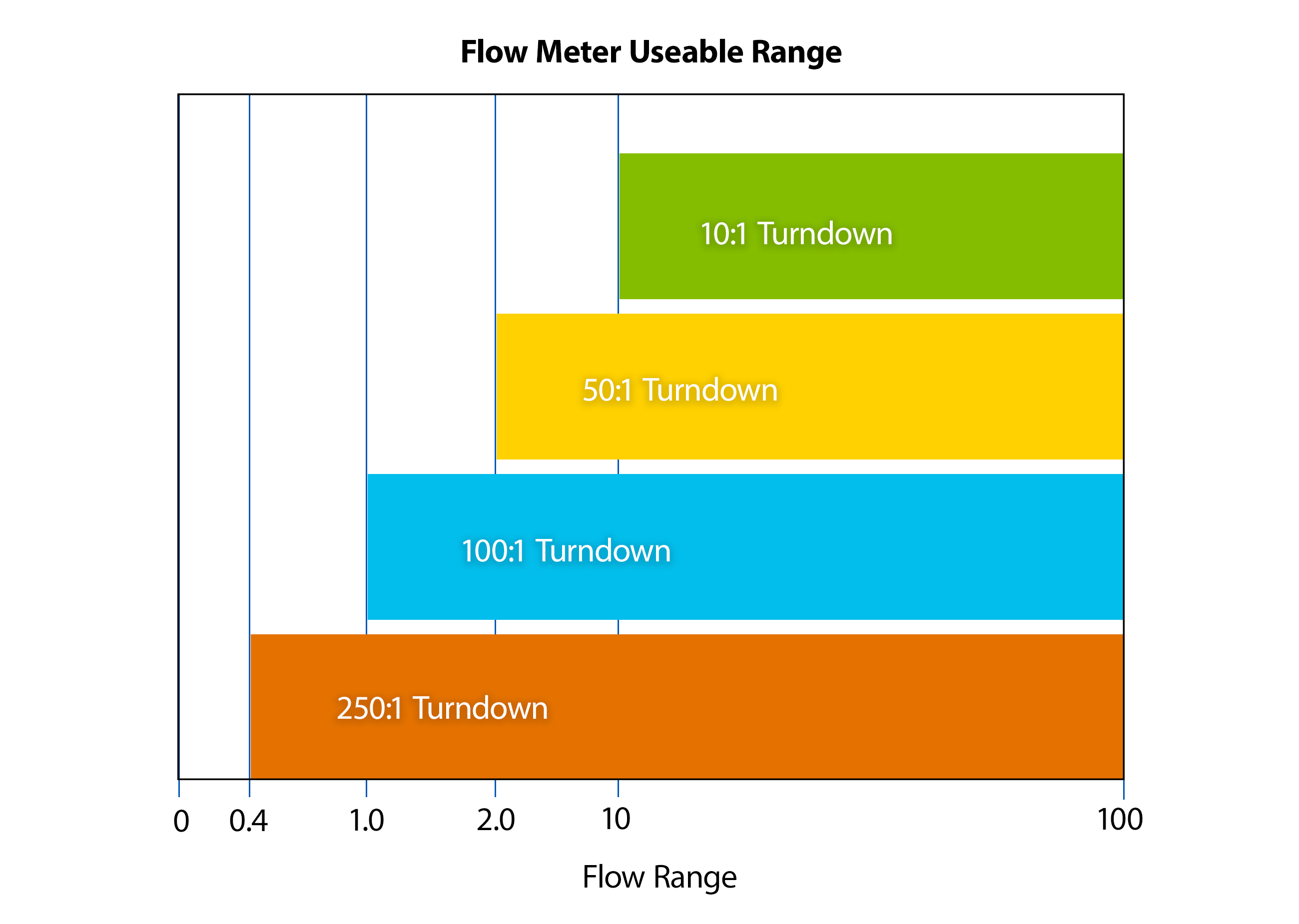

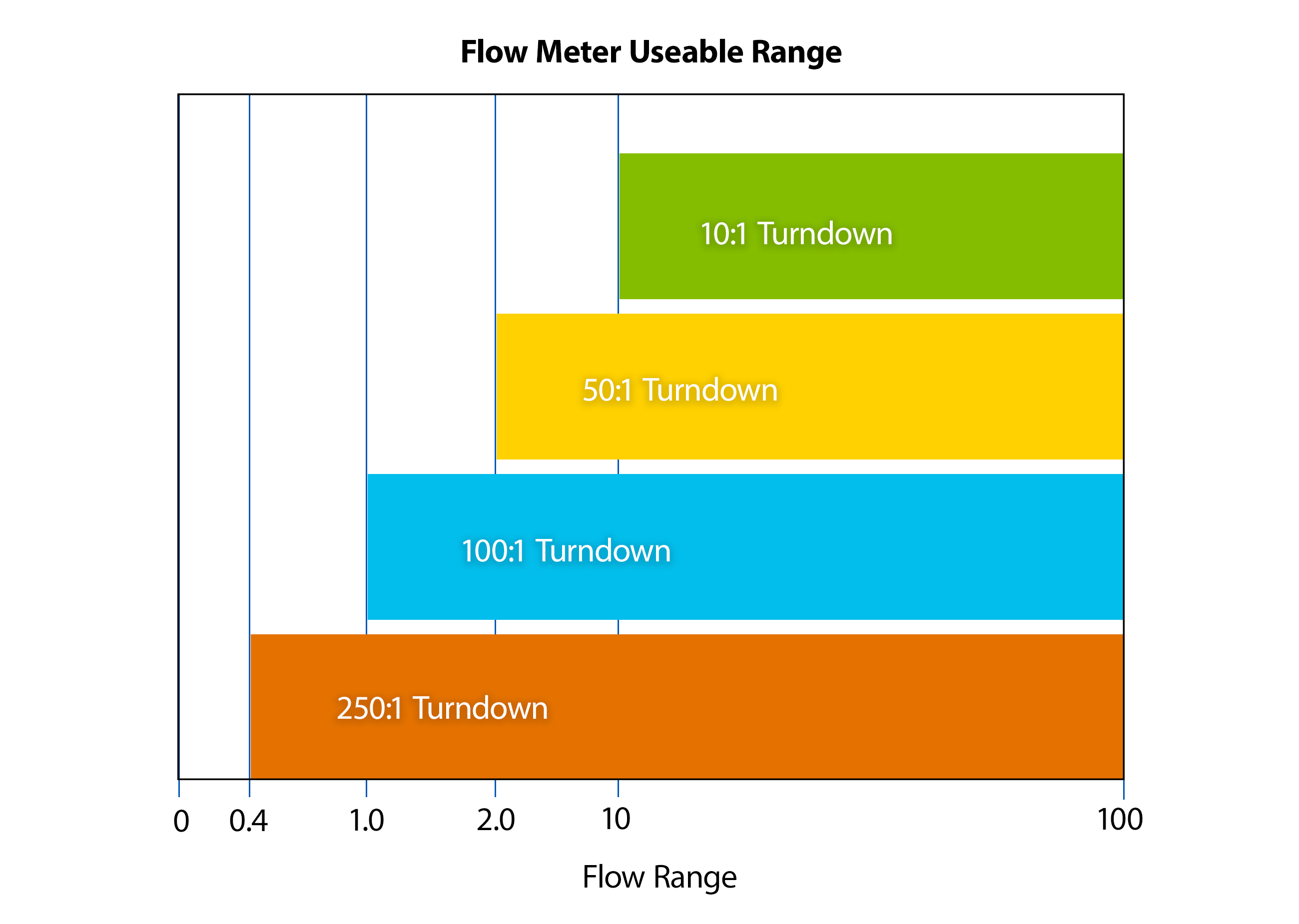

When the error of the device at a given rate is 100% of rate or greater the device is typically said to be unusable in that range. For the variable area flow meter, when the turndown exceeds 10:1 the error as a % of rate exceeds 100% of rate. This area is highlighted red. Similarly on the the other columns depicting typical gas flow controller accuracy specifications. Depending on the accuracy specification, the usable range may be as high as 250:1, as is the case with the Brooks Instrument SLA5800 Series mass flow controllers.

The Control Valve Makes a Difference

The ability of the valve to maintain stable control at low flow rates / wide turndowns is the next consideration. The device can only control down to the maximum leak rate past the valve. As these are control valves, NOT shut off valves, the ability of the valve to control at very low rates depends on that valve being almost as good as a shut off valve. This depends on the type of control valve, the valve seat material, the full scale range of the device and how the device is set up for dynamic response. If you have a 100 sccm device (nice low full scale flow rate) with a 1000:1 turndown, that valve needs to “shut off” to less than 0.1 sccm. If you have a valve with a wide control range, elastomer valve seat and a reasonable (relatively slow) response time, this type of “shut off” / turndown is possible. But in more challenging applications where the valve seat is metal or PTFE, or the line pressure is high (reduced valve control range), or the dynamic response is tuned to be fast acting, the ability of that control valve to “shut off” will be compromised. While a device spec sheet may claim wide turndown, be sure you understand the practical limitations of that valve and as its ability to “shut down”.

Why "Usable Range" is Important

So who cares about usable range and why? Most users of flow measurement and control devices care about the turndown and more importantly the usable range. In some cases the user can reduce the number of mass flow controllers required in a system, or spares required in inventory by taking advantage of a wide usable range.

In thin film deposition applications (semiconductor, solar cell, fiber optic, metal and glass coating), there may be multiple steps in the process some with high flow rates and some with low. Having a device with a wide usable range could reduce the number of gas flow controllers required in the system to cover the full range of flow rates required. In these applications they typically determine the set point that delivers the desired results and rely on the repeatability of the device to deliver the desired result.

In chemical and petrochemical research applications, the wider the usable range the more flexibility the users gets from the device. But, in these applications they are often doing mass balance on all of the feeds / inputs and product & waste / outputs and accuracy tends to be very important. With the desire for high accuracy, the usable range may be limited.

For biotech applications some processes require extremely low oxygen flow rates during start up but these rates quickly scale up. Similar to the thin film application described above, the user may be able to reduce the number of mass flow controllers required on the oxygen line if the MFC is able to deliver good consistent results with low signal to noise and reasonable response times.

In summary, the usable range of any instrument depends on the practical limits of the instrument as well as the requirements of the application. The more stringent the accuracy requirements the more limited the usable range. Be sure to understand the application requirements as well as the real practical limits of the device(s) being considered at the actual operating conditions.

Please contact Brooks Instrument to learn more about our SLA Biotech Package with enhanced valve shut off, wide turndown, enhanced materials, certifications and approvals. Or feel free to ask the experts at Brooks Instrument if you need assistance on any flow or pressure measurement and control application.