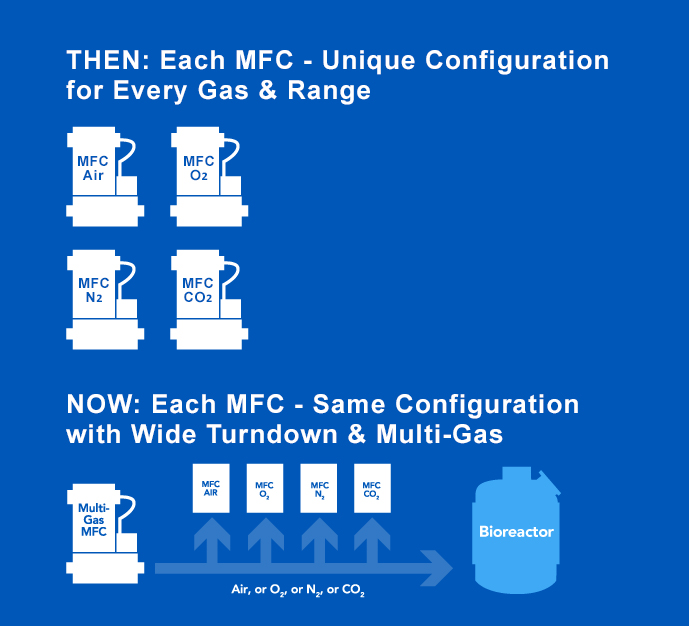

Thermal mass flow controllers (MFCs) are traditionally calibrated for a specific gas – typically a surrogate such as Nitrogen (N2) - a desired flow range, and a set of operating conditions. Over time, the use of conversion factors based on a ratio of specific heats between the surrogate and the desired gas came into use as a way for users to configure a single mass flow controller for multiple gases. This method for configuring multiple gases is at the heart of the Brooks Instrument SLA Series Biotech MFC .

Specifically, the performance package on the SLA Series Biotech includes the four key gasses used in bioprocessing, pre-configured on the device (gas pages):

- Nitrogen

- Carbon Dioxide

- Oxygen

- Air

The device is sized for the specific gas chosen by the user at time of order, that is the configuration gas. The calibration curves are obtained by use of N

2 as a surrogate gas. If actual CO

2 gas is chosen, then the device is calibrated on CO

2 and N

2 surrogate for the remaining gasses, at an extra charge.

Application of Multiple Biotech Gasses Configured in One MFC

A high turndown ratio, and pre-calibrated gas pages means that each configuration can be used for multiple-sized systems and different gasses, reducing the number of MFC configurations required by up to 90%. That is, an OEM or end user might have a large number of part numbers to support due to the number of different gases and flow ranges that they use in their range of equipment. Multiple gas pages, like those available with the SLA Series Biotech MFC, takes those different devices and condenses them into a few or limited number of MFCs (mass flow controllers) allowing reduced production inventory and reduced and simplified after-sale service inventory. For example, an OEM who manufactures six different sized bioreactors, between 10 LPM – 2000 LPM - can satisfy all specified reactor flow control requirements with six MFC configurations, each loaded with four gas pages and stay within limits of MFC turndown.

How Multiple Gas Pages Work

Each gas has a “page” that includes a calibration curve, PID controller settings, valve performance data, and information about the calibration conditions. The active gas page will be the configuration gas, which will be listed on ordering documents, and the top label of the controller. The other three gas ranges will also be listed on the controller label.

The operator can change the active gas “page” either through the Brooks Expert Support Tool (BEST) software or through the digital communications protocols if the device is so equipped.

When using BEST, the pages will appear in the calibration table in the same order as noted above: Air will appear as calibration #1, N2 as calibration #2 and so on. For more detailed instructions on how to activate gas pages using BEST, please see the Cal Pages and Flow Cal Pages section of the Installation and Operations manual for BEST.